The Ultimate Overview to Getting Used Engines for Sale with Self-confidence

Crucial Factors To Consider for Guaranteeing Quality and Durability in operation Engines

When thinking about the purchase of a used engine, ensuring its high quality and durability needs a diverse technique. Maintenance history is an essential variable, as it gives understanding right into the engine's previous treatment and prospective future dependability. Beyond paperwork, an in-depth examination of physical parts-- such as belts, tubes, and seals-- can disclose surprise concerns. Efficiency testing is likewise vital, using a picture of the engine's operational effectiveness. Nevertheless, comprehending the nuances of these assessments and their implications can be complex. What are the crucial approaches that can be employed to browse this detailed evaluation process efficiently?

Engine Background Evaluation

In the realm of made use of engines, an extensive engine background assessment is vital to guaranteeing top quality and reliability. Recognizing an engine's past can provide vital understandings into its efficiency abilities and potential future long life.

Engines that have undertaken substantial repair services may have underlying issues that might resurface. Taking a look at the engine's mileage can offer as a sign of wear and tear. An engine used primarily for long-distance freeway driving may be in better problem than one subjected to constant stop-and-go city web traffic.

Essentially, an exhaustive investigation right into an engine's history is vital for making educated getting decisions. used engines for sale.

Comprehensive Evaluation Guide

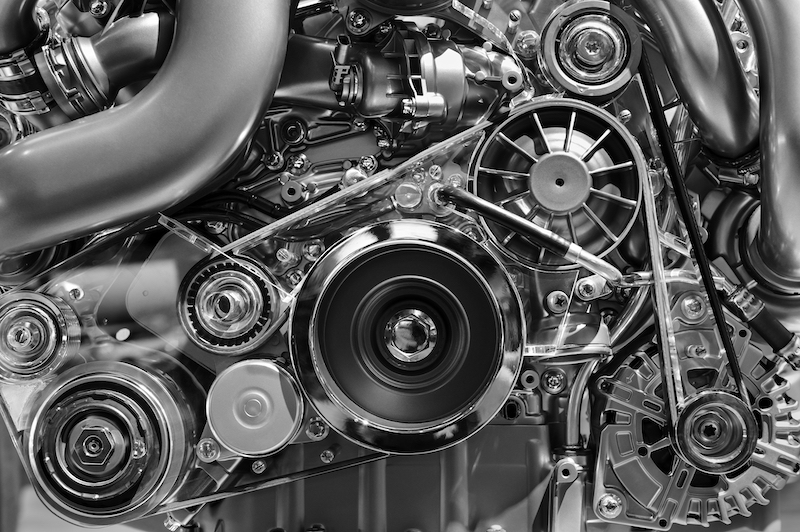

While understanding an engine's history gives beneficial context, a comprehensive inspection is the next step to ensure its existing problem lines up with historical data. The assessment needs to start with a visual evaluation, checking for indicators of leaks, rust, and uncommon wear. Inspect the exterior for oil discolorations or coolant marks, which may suggest underlying concerns.

Next, review the engine's mounting system for any type of loosened screws or abnormalities that might affect efficiency. Pay very close attention to the problem of belts and hose pipes, as these parts are vital for optimal engine capability. Check out for fractures, fraying, or any kind of indications of damage.

Recognizing Put On and Tear

Identifying indicators of wear and tear is essential for evaluating an utilized engine's durability and dependability. It includes a precise evaluation of different engine elements to identify their current state and potential future performance. Common indicators consist of visible deterioration, which can influence metal components and endanger architectural honesty. Corrosion on or around the engine block, cyndrical tube heads, and exhaust manifolds is especially concerning.

Another critical facet is checking the engine's seals and gaskets. These components are essential for preserving appropriate pressure and avoiding fluid leaks. Proof of oil leaks or worn gaskets frequently recommends wear and tear, possibly bring about much more extreme issues if not addressed quickly. In addition, unusual sounds throughout engine operation, such as knocking or try this out ticking noises, may show interior damages or extreme endure moving components like pistons or bearings.

The condition of belts and hose pipes is similarly essential, as they play an important role in the engine's general function. Broken or frayed belts and weak hoses are indications of maturing that might result in engine failure if disregarded. Finally, taking a look at the oil condition and filter can provide insights right into previous maintenance practices, as filthy oil or stopped up filters suggest overlook and sped up wear.

Efficiency Screening Fundamentals

Evaluating the damage of engine elements sets the phase for a detailed evaluation through efficiency screening. Performance screening functions as an essential measure in figuring out the operational integrity of a made use of engine. By mimicing real-world conditions, it examines the engine's capability to deliver power efficiently and accurately. Secret metrics include horse power, torque, fuel efficiency, and exhausts degrees. This data provides beneficial understandings into the engine's existing efficiency and helps recognize prospective issues that might not be quickly visible.

Utilizing dynamometers is an usual technique in performance screening. These tools determine the engine's outcome throughout numerous conditions, providing a comprehensive profile of its performance. In addition, on-road testing matches dynamometer assessments by observing engine actions under common driving scenarios, guaranteeing it satisfies the called for requirements for both security and performance.

Advanced diagnostic tools better enhance the ability to determine underlying concerns. These tools analyze engine administration systems, recognizing mistakes in digital components that could impact efficiency. Comprehensive screening not just validates the engine's operational status however also help in projecting future upkeep demands. This ensures the utilized engine can supply reliable performance over an extensive duration, therefore maximizing its worth and solution life.

Upkeep and Treatment Tips

Proper upkeep and care are critical to prolonging the life expectancy of a made use of engine and ensuring its constant performance. Normal oil adjustments are vital; utilizing the supplier's advised oil type and quality can stop too much damage. Additionally, oil filters need to be changed simultaneously to keep optimum lubrication and sanitation within the engine.

Checking fluid degrees, including coolant, transmission fluid, and brake fluid, is crucial. Ensuring these fluids go to appropriate degrees helps avoid getting too hot and various other mechanical problems. Checking belts website here and pipes for signs of wear, such as fractures or fraying, can prevent prospective Going Here failures that might lead to costly fixings.

Regular assessment of the air filter is likewise necessary, as a clean filter guarantees reliable air flow and burning, therefore maximizing engine performance. Ignition system ought to be inspected and replaced when needed to keep efficient fuel combustion and avoid engine misfires.

Last but not least, regular diagnostic checks using specialist devices can identify prospective concerns prior to they become considerable issues. By sticking to these upkeep and treatment tips, made use of engine proprietors can ensure their engines continue to be trusted, efficient, and qualified of executing more than a prolonged period.

Conclusion